The Solenoid valve can be described as an essential control unit of modern pneumatic and fluid control systems and is used in numerous applications such as industrial automation, HVAC, and various other processes.

Through the conversion of electric signals to mechanical motion, solenoid valves provide accurate and repeatable control of air, gases, water, oil, and other fluids in a PLC-controlled and intelligent system.

Being a dedicated pneumatic components supplier, CHDAC also develops and distributes solenoid valves designed with a focus on promptness, sealing, and longevity, catering to the worldwide market of OEMs, automation device manufacturers, and system integrators.

This article will define what a solenoid valve is, its working, applications, market trends, technical comparisons, and finally provide an insight into how a solenoid valve needs to be selected for industrial application.

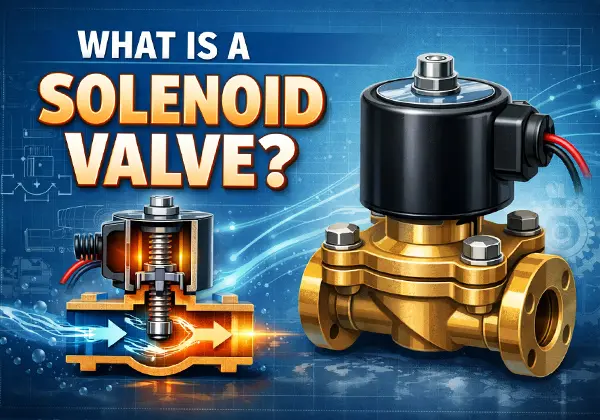

What Is a Solenoid Valve? Definition and Core Concept

A solenoid valve is an electromechanically operated type of valve, using an electric current to operate a magnetic field, which in turn causes a mechanical plunger to open, shut, or shift flow direction in a fluid.

In practical industrial terms:

Electrical signal → Magnetic force → Mechanical movement → Fluid or air flow control

Due to their fast switching speed, compact design, and easy integration with automation controls, solenoid valves remain one of the most common control elements in fluid power systems. According to Wikipedia, they are a core component in modern fluidics and pneumatic systems.

Key Characteristics of Industrial Solenoid Valves

- Electrically operated, AC or DC power

- Low latency, typically measured in milliseconds

- Compact and sturdy structure

- Designed for automated and unmanned systems

- Compatible with air, water, gas, oil, and a wide range of industrial fluids

Main Components of an Industrial Solenoid Valve

Typical Basic Components of the Industrial Solenoid Valve:

Solenoid Coil

It generates a magnetic field upon energization with an electrical signal.

Plunger (Armature)

Moves linearly under the magnetic force, to open or close the valve.

Return Spring

Ensures the valve returns to its default position upon removal of power.

Valve Body

Has flow channels and ports; usually in brass, stainless steel or aluminum.

Seals and Diaphragm

Provide leakage-free service with chemical compatibility in most cases by using NBR, FKM, EPDM, or PTFE.

The simple but robust construction enables a solenoid valve to function steadily in high-cycling industrial settings.

How Does a Solenoid Valve Work? Step-by-Step Operating Principle

A solenoid valve functions by using electrical energy to mechanically regulate the flow of fluids or air.

Operating Process Explained

- When an electric signal is introduced, the solenoid coil is activated.

- This energized coil produces a magnetic field.

- The magnetic field exerts a pulling force on the plunger despite the repulsion by the spring.

- The action of moving the plunger results in opening, closing, or diverting the flow path.

- The moment the power is switched off, the magnetic force fades away and the spring pushes the plunger to its initial position.

Normally Closed vs Normally Open Solenoid Valves

Normally Closed (NC) Solenoid Valve

The valve is closed when there is no power.

Turning the power on: the valve will open.

Normally Open (NO) Solenoid Valve

No power → valve open

Turn power on, and valve will close

Such control logic makes solenoid valves very appropriate in PLC-controlled automation, pneumatic circuits, as well as in safety applications.

Types of Solenoid Valves Used in Industrial Automation

Solenoid Valves by Function

2Way Solenoid Valve: Simple on/off flow control

3 Way Solenoid Valve: Directional control (commonly used in pneumatics)

5-Way Solenoid Valve: Designed for double-acting pneumatic cylinders

Solenoid Valves based on Operating Method

Direct-acting solenoid

Pilot operated solenoid valve

Semi-direct acting solenoid

Solenoid Valves by Media Type

Pneumatic solenoid valves (compressed air)

Water solenoid valves

Gas solenoid valves

Oil and chemical solenoid valves

CHDAC mainly develops pneumatic solenoid valves designed for industrial automation and other applications.

Key Applications of Industrial Solenoid Valves

The valve solenoid finds wide applications in the following industries:

Industrial Automation

Pneumatic cylinders and actuators

Assembly and packaging machinery

Automated production lines

HVAC and Building Systems

Control of water and refrigerant flow

Energy-efficient system management

Water Treatment and Environmental Systems

Filtration and dosing systems

Smart irrigation and distribution networks

Medical and Laboratory Equipment

Oxygen and gas flow control

Diagnostic and analytical devices

Chemical and Process Industries

Chemical processing systems

Oil and gas control applications

Industry leading automation manufacturers of intelligent fluid control architectures include ABB and Schneider Electric.

Solenoid Valve Market Trends and Industry Background

The world market for solenoid valves is expanding because of:

- Fast adoption of industrial automation

- Smart factories and Industry 4.0 developments:

- Rising demand for energy-efficient solutions

- Increase in OEM machinery manufacturing globally

Industry sources quoted by IEEMA and leading automation manufacturers report that electrically actuated solenoid valves are increasingly being used to substitute manual valves because of increased control accuracy and less down time.

Key Technical Parameters of Industrial Solenoid Valves

| Parameter | Typical Range |

|---|---|

| Operating Pressure | 0.1 – 10 bar (air) |

| Voltage | 12V / 24V DC, 110V / 220V AC |

| Response Time | 10–50 ms |

| Media Temperature | −10°C to 80°C |

| Protection Class | IP65 / IP67 |

CHDAC solenoid valves are also tested for their cycle life, seal, and performance characteristics with continuous industrial applications.

Solenoid Valves vs Manual Valves vs Motorized Valves

| Feature | Solenoid Valve | Manual Valve | Motorized Valve |

|---|---|---|---|

| Automation Compatibility | Excellent | None | Good |

| Response Speed | Very fast | Slow | Moderate |

| Control Accuracy | High | Low | High |

| Cost | Moderate | Low | High |

| Maintenance | Low | Low | Higher |

In most of the pneumatics and fluid automation systems that demand fast responsiveness and frequent switching operations, solenoid valves offer the most optimal combination of performance, automation compatibility, as well as cost-effectiveness.

How to Choose the Right Solenoid Valve for Your Application

When choosing an industrial solenoid valve, the following should be taken into account:

- Medium type: air, water, gas, oil

- Operating pressure, flow rate required

- Voltage and power supply

- Port size(Thread standard)

- Normally open or normally closed construction

- External conditions of use: temperature, humidity, dust

CHDAC provides tailored services for solenoid valves with voltage customisation, manifold mounting options, and private labeling in OEM and Automation projects.

Why Choose CHDAC Industrial Solenoid Valves?

- Specializing in pneumatic components manufacturing

- Stable and consistent quality for worldwide markets

- Customization for OEM & ODM orders

- Strict quality control and performance testing

- Long-term supply and production stability

Design of the solenoid valve by CHDAC takes into account the needs of industrial automation, thereby helping the company’s clients to construct competent systems.

FAQ

Q1: In what way do AC and DC solenoid valves differ in their use in industrial processes?

DC solenoid valves have faster response times and operate quietly, but they are less tolerant of voltage variation, whereas AC solenoid valves.

Q2: Can Industrial Solenoid Valves be Used Continuously?

Yes. When properly specified, industrial solenoid valves are rated for continuous duty.

Q3: What happens to a solenoid valve in the case of a power outage?

The valve reverts to its normal position, which may be normally closed or normally open.

Q4: What is the lifespan of the industrial solenoid valve?

High-quality solenoid valves will exceed 10 to 50 million cycles, depending on conditions.

Q5: Are solenoid valves appropriate for controlling pneumatic cylinders?

Yes. Solenoid valves are basic control elements of single-acting as well as double-acting pneumatic cylinders.

Conclusion

The solenoid valve is a critical component that empowers modern industrial systems to manage fluids and gases with such accuracy, reliability, and automation. Its combination of electrical control, mechanical simplicity, and fast response thereby makes it indispensable in automation and pneumatic applications.

As a trusted pneumatic components manufacturer, CHDAC delivers industrial solenoid valves engineered for durability and performance according to global standards, while continuing to support Original Equipment Manufacturers and automation systems across the world.