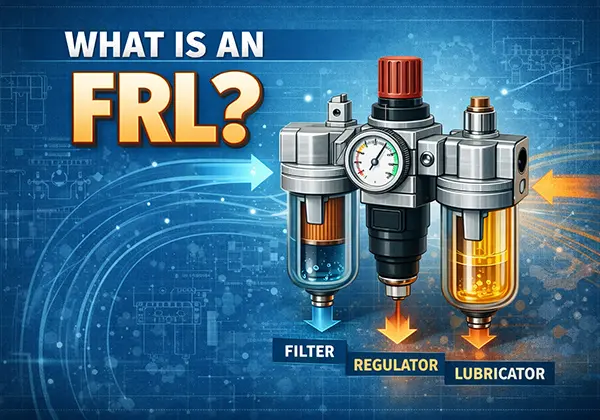

FRL is most commonly associated with “Filter, Regulator, Lubricator,” which is an important part of pneumatic systems.

An FRL is a type of pneumatic air treatment assembly that is capable of not only filtering the air but also controlling air pressures. This assembly is used before the pneumatic devices. Such devices can be air cylinders, solenoid valves, or air tools.

In the case of industrial automation systems, appropriate air preparation through FRL has a direct bearing on the life of the system’s equipment, its reliability, as well as the cost incurred during its.

What Does FRL Mean in Pneumatic Systems?

In FRL stands for a three-element pneumatic component package installed in a series. Each element serves a different function in determining the quality of compressed air.

Pneumatic Air Filter (F in FRL)

The pneumatic air filter is used to clean the compressed air by separating any impurities, including:

- Dust and solid particles

- Condensed Water and Moisture

- Oil aerosols (depending on the filter grade)

To avoid contamination, the air filter safeguards pneumatic valves, pneumatic cylinders, pneumatic seals, and pneumatic internal moving parts from wear and tear or rust.

Air Pressure Regulator (R in FRL)

The air pressure regulator regulates and maintains a constant pressure of compressed air to a set value called for in the pneumatic system.

Benefits for pressure regulation include:

- Uniform actuator speed and force

- Increased operational precision

- System safety improvements

- Lower air usage and energy dissipation

Stable pressure is a crucial consideration, especially in precise pneumatic automation.

Pneumatic Lubricator (L in FRL)

It adds a controlled mist of lubricating oil to the compressed air stream.

Lubrication aids in:

- Reduce friction between moving parts

- Minimize Seal Wear

- Prolong the lifecycle of air cylinders, pneumatic valves, and air tools

Note: In modern systems, lubrication may not be necessary in many cases, particularly for oil-free pneumatic components.

Why FRL Units Are Important in Pneumatic Systems

Properly selected FRL air preparation in turn helps manufacturers and system integrators to:

- Extend pneumatic equipment lifespan

- Cut unplanned downtime

- Smaller maintenance and replacement costs

- Improve overall system dependability

- Prevent corrosion and failure of internal components

The best practice for pneumatic performance is realized with proper air filtration and pressure control, according to compressed air quality standards like ISO 8573.

Typical Applications of FRL Units

FRL units find wide application in industrial and manufacturing environments including:

- Pneumatic cylinders along with solenoid valve systems

- Industrial automation, and robotic equipment

- Manufacturing and assembly lines

- Packaging and food processing machinery

- Air tools, workshops, and maintenance stations

A proper FRL configuration ensures stability in operations for both OEM pneumatic systems and end-user installations.

FRL vs Individual Pneumatic Components

| Configuration | Advantages | Typical Applications |

|---|---|---|

| Integrated FRL Unit | Compact design, easy installation, reduced leakage points | Standard industrial pneumatic systems |

| Separate Filter, Regulator, Lubricator | Flexible layout, higher customization | Special-purpose or high-precision pneumatic setups |

Popular FRL Configurations and Variations

FR Unit (Filter & Regulator)

An FR unit is normally used when there is no need to lubricate, in cases like:

- Clean-room environments

- Food and Pharmaceutical Machines

- Systems with maintenance-free pneumatic components

Modular FRL Systems

The Modular FRL unit enables the addition or subtraction of functional modules from the system, such that the following can be added

- Pressure Gauges

- Soft-start valves

- Shut-off or dump Valves

- Further fine filtering stages

This modular design is optimal for the design and integration of custom pneumatic systems.

How to Choose the Right FRL Uni

When selecting an FRL for a pneumatic system, consider:

- Required air flow rate (L/min or SCFM)

- Operating pressure range

- Filtration accuracy (micron rating)

- Lubrication requirements

- Installation space and port size

A proper FRL provides optimal air quality, and unnecessary pressure loss is avoided.

Summary: What Is an FRL?

→ FRL = Filter + Regulator + Lubricator → A necessary pneumatic air preparation unit → Provides clean, steady, and well-conditioned compressed air

A properly set up FRL system is an essential part of any good pneumatic automation system.

When choosing FRL units for OEM or industrial use, it is essential for you to comprehend air quality needs and system parameters if you are to provide a stable, functioning device.