What Is a Compact Double Acting Air Cylinder?

A double acting air cylinder uses compressed air to actuate the piston in both directions of extension as well as retraction. Unlike single acting cylinders that require a spring return action, double acting cylinders have the advantage of:

- Controlled force in both directions

- Improved stability in positioning

- Speed control

- Improved performance during continuous operation

The SDA compact cylinder has a shorter body length compared to standard ISO cylinders. This makes it useful for equipment with limited mounting space.

It can also be referred to as:

- Compact pneumatic actuator

- Mini air cylinder

- Space saving pneumatic cylinder

- Aluminum body air cylinder

| Model NO. | SDA12/16/20/25/32/40/50/63/80 |

| Double-Acting Cylinder Type | Piston Cylinder |

| Port Size | 12,16,20,25,32,40,50,63,80…. |

| Power | Pneumatic |

| Pressure Direction | Double-acting Cylinder |

| Transport Package | Wooden Case, Pallet, Seal Paper, Carton |

| Origin | Wenzhou Zhejiang China |

| Production Capacity | 10000 Piece Per Month |

Key Features of CHDAC SDA Compact Cylinder

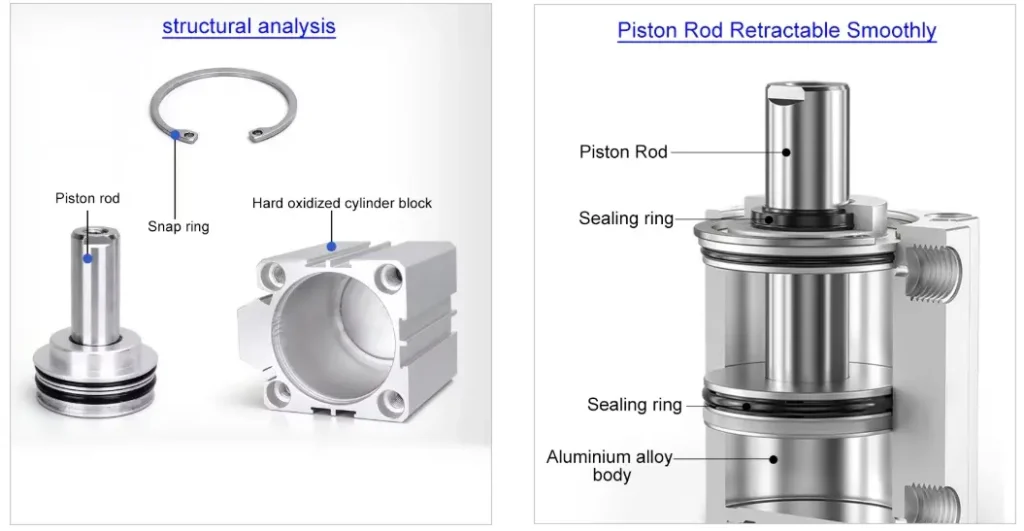

1. Space-Saving Aluminum Structure

The high-strength aluminum alloy body is precision machined to reduce overall length while maintaining rigidity. Compared with traditional tie-rod cylinders, the SDA compact air cylinder significantly reduces installation footprint.

Ideal for:

- Automated assembly lines

- Pick-and-place systems

- Clamping fixtures

- Labeling and packaging equipment

2. Durable Materials for Long Service Life

- Piston Rod: #45 steel (ASTM 1045 equivalent), hard chrome plated

- Optional stainless steel piston rod for corrosive environments

- Wear-resistant seals for stable performance

- Built-in rubber buffer (adjustable air cushion optional)

- Self-lubricating bearing design

These materials ensure long service life even under frequent cycling conditions.

3. Optional Built-in Magnet for Position Sensing

The SDA series can be supplied with an internal magnet (S type), compatible with reed switches and proximity sensors.

This allows:

- Accurate stroke detection

- Automation integration

- PLC position feedback control

Especially suitable for smart manufacturing and automated systems.

4. Stable Operating Performance

- Operating Pressure: 0.1 – 1.0 MPa

- Maximum Pressure Resistance: 1.5 MPa

- Operating Speed: 30 – 500 mm/s

- Ambient Temperature: -5°C to 70°C

- Working Medium: Clean, filtered compressed air

In real production environments, these parameters ensure smooth motion and stable output force during continuous operation.

Technical Specifications

| Specification | Value |

|---|---|

| Bore Size | 12, 16, 20, 25, 32, 40, 50, 63, 80, 100 mm |

| Action Type | Double Acting / Single Acting |

| Stroke Length | Customizable |

| Cushioning | Rubber Buffer / Adjustable Air Cushion |

| Port Size | M5×0.8 – G3/8 |

| Body Material | Aluminum Alloy |

| Mounting Type | Standard Compact Mounting |

Custom stroke lengths are available upon request.

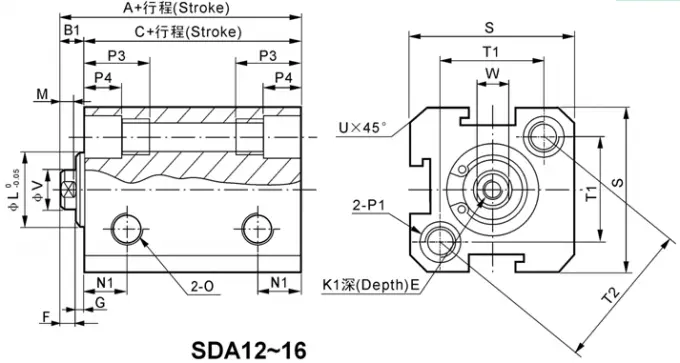

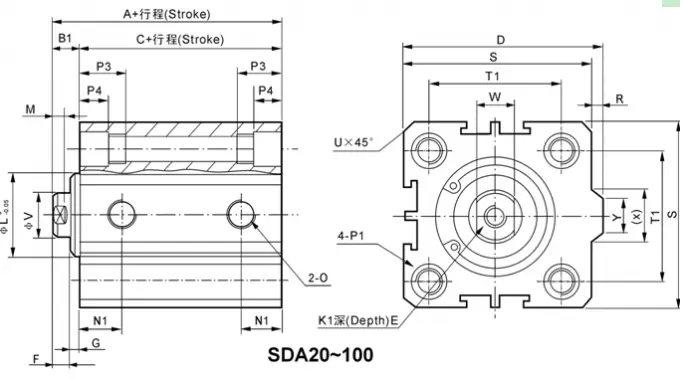

SDA Compact Cylinder Dimensions & CAD Files

For engineering integration, CHDAC provides:

- 2D dimensional drawings (PDF)

- 3D CAD models (STEP format)

- Installation size reference

- Mounting hole details

The SDA compact air cylinder follows standardized mounting dimensions for easy replacement and OEM integration.

Contact us to receive detailed technical drawings.

Ordering Code Example

Example: SDA 20 50 S F

- SDA – Standard double acting type

- 20 – Bore size (20mm)

- 50 – Stroke length (50mm)

- S – With magnet

- F – Female thread rod end

Other available options:

- M – Male thread rod

- SDAD – Double piston rod type

- SDAJ – Adjustable stroke type

- SSA / STA – Single acting type

OEM customization is supported.

Applications

The SDA series compact pneumatic cylinder is widely used in:

- Packaging machinery

- Electronics & semiconductor equipment

- Textile machinery

- Food processing automation

- Robotics gripping systems

- Industrial clamping systems

- Fixture positioning devices

Its short body design makes it ideal for compact equipment layouts where space efficiency is critical.

SDA vs Standard ISO Cylinder

| Feature | SDA Compact Cylinder | Standard ISO Cylinder |

|---|---|---|

| Body Length | Short / Compact | Longer |

| Installation Space | Minimal | Larger |

| Weight | Lightweight | Heavier |

| Typical Use | Equipment integration | Heavy-duty machinery |

| Best For | Limited space applications | High-force applications |

If your equipment requires compact installation and moderate force output, SDA is usually the more efficient choice.

How to Select the Right Compact Air Cylinder

When choosing an SDA compact double acting cylinder, consider:

1. Required Output Force

Force (N) = Pressure (MPa) × Piston Area (mm²)

Example:

At 0.6 MPa, a 32mm bore cylinder can generate approximately 480N theoretical force.

Select bore size based on required load and safety factor.

2. Stroke Length

Define the exact working travel distance. Custom strokes are available.

3. Mounting Space

Confirm installation dimensions and port orientation before selection.

4. Sensor Requirement

Choose magnet type (S option) if position detection is required.

5. Working Environment

For humid or corrosive environments, stainless steel piston rod is recommended.

Why Choose CHDAC as Your Pneumatic Cylinder Supplier?

- 10+ years manufacturing experience in pneumatic components

- Strict ISO9001 quality management system

- 100% pressure and leakage testing before shipment

- OEM branding & customized configurations supported

- Stable quality for distributors and equipment manufacturers

- Competitive factory-direct pricing

- Fast delivery for standard SDA models

We support global OEM customers, automation integrators, and pneumatic distributors.

FAQ

A compact air cylinder has a shorter body length while maintaining similar bore size and force output. It is mainly used where installation space is limited.

It uses self-lubricating components and can operate with non-lubricated compressed air. Clean, filtered air is recommended.

Yes. Depending on bore size and load conditions, operating speed can reach up to 500 mm/s. Flow control valves are recommended for speed adjustment.

Yes. The SDA compact cylinder follows mainstream compact cylinder dimensions, allowing easy replacement in existing equipment.

Request a Quote

If you are looking for a reliable compact air cylinder manufacturer or need customized stroke solutions, CHDAC provides professional technical support and fast quotation service.

CHDAC – Your Trusted Pneumatic Components Manufacturer.